LINK COMPOSITES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to LINK COMPOSITES P.LTD.

Chopped Strand Mat

Product Description

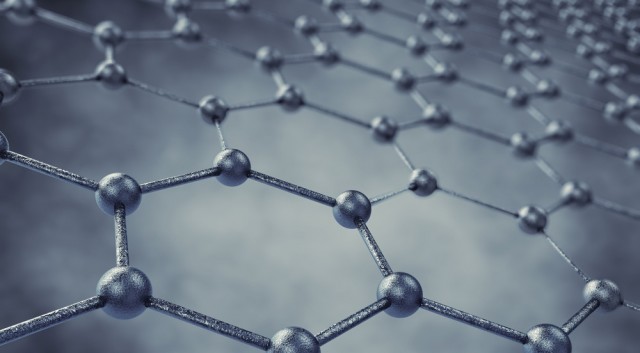

CSM mat is made of randomly oriented chopped glass strands bonded together in mat form using an emulsion binder. The emulsion binder uniquely bonds the mat so that it conforms rapidly to highly contoured molds. It is a porous, well bonded mat which maintains its integrity during the impregnation process and provides an uniform wet-through rate. The emulsion binder produces superior handling properties compared to powder bonded mats.

Product Application

- CSM mat is a reinforcement for use with unsaturated polyester resins in the hand lay-up process. Ideal for applications such as auto parts, boats, chemical tanks and swimming pools.

- Typical applications are those which require a high glass content and good mechanical properties. CSM is ideal in applications requiring rapid impregnation and excellent wetting. CSM has excellent handling and tailoring properties as well as the ability to conform rapidly to even the most complex molds.

Features And Product Benefits

- Excellent impregnation properties

- Excellent conformability

- Good mechanical properties

- Quick wetting with rapid air release maximizes holding productivity and reduces resin demand, thereby reducing costs

- The ease of handling and ability to conform rapidly to complex molds helps in making high quality parts with ease

- Good bonding with low resin demand provides excellent laminate properties as demonstrated with the Lloyds/dnv certifications

Product Availability

| STANDARD WEIGHT (G/M2) | STANDARD WIDTH (CM) |

|---|---|

| 300, 450,600, 900 | 95, 104,125 |

- Additional weights and widths may be available upon request.

Mechanical Properties

The following are the typical laminate properties of CSM in an orthophthalic polyester resin, glass content 31% by weight, molded by hand lay-up using Lloyd’s specifications. CSM shows excellent performance equal to and/or exceeding competitive products.

CSM is approved by Lloyd’s Register of Shipping and Det Norsk Veritas.

| PROPERTY | METHOD | UNIT | CSM |

|---|---|---|---|

| Tensile Strength | ISO3268/DIN 53455 | Mpa | 108 |

| Tensile Elongation | ISO3268/DIN 53455 | % | 1.8 |

| Tensile Modulus | ISO3268/DIN 53455 | Mpa | 7800 |

| Flexural Modulus | ISO 178 | Mpa | 6770 |

| Flexural Strength | ISO 178 | Mpa | 204 |

| Flexural Elongation | ISO 178 | % | 3.4 |

Packaging (standard ref.)

| MAT WIDTH (CM) | ROLL DIAMETER (CM) | ROLL WEIGHT (KG) | ROLLS / PALLET | PALLET SIZE (CM) |

|---|---|---|---|---|

| 95 | 30 | 41 | 12 | 127 x 97 |

| 104 | 27 | 32 | 16 | 113 x 113 |

| 125 | 30 | 55 | 12 | 127 x 97 |

CSM mat is wound into a roll on a 3-inch diameter cardboard inner tube. Rolls consist of a single continuous length of mat. If a break occurs in the mat, it is marked with a colored paper slip. A maximum of three breaks are allowed in any one roll.

Labelling

- Each roll bears a label stating product description, product nominal weight (g/m2), product roll width, product code, net weight, production number and shift number, roll number.

- Mat rolls are supplied in a protective polythene bag in a one-piece carton box. These are placed vertically on wooden pallets and shrink-wrapped for stability and protection.

Storage

It is recommended that glass fiber products are stored in a cool dry area. Temperature should not exceed 35°C and the relative humidity should be kept below 75%. The glass fiber material should remain in its packing material until just prior to use. To avoid moisture pick-up on the glass, care should be taken not to open a container prior to conditioning to room temperature.

To avoid damage to the products and to ensure safety, pallets should be stacked no more than two high.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.